How to Start a T-Shirt Business at Home | Key Things to Know!

Last updated: May 18, 2023

The video by Stahls' TV is about how to start a t-shirt business from home using a heat press and different types of heat transfer methods.

The video is about starting a t-shirt business from home using a heat press machine.

The speaker, Josh Ellsworth, explains the different types of heat transfer methods, including screen printed transfers, heat transfer vinyl, print cut heat transfer vinyl, and digital screen printed transfers.

He emphasizes the profitability of using a heat press machine and provides tips on how to order the right transfer, ensure an accurate press, and find customers to sell to.

Ellsworth also showcases Transfer Express, a division of Stahls, which manufactures screen printed transfers that can be heat applied in four seconds or less.

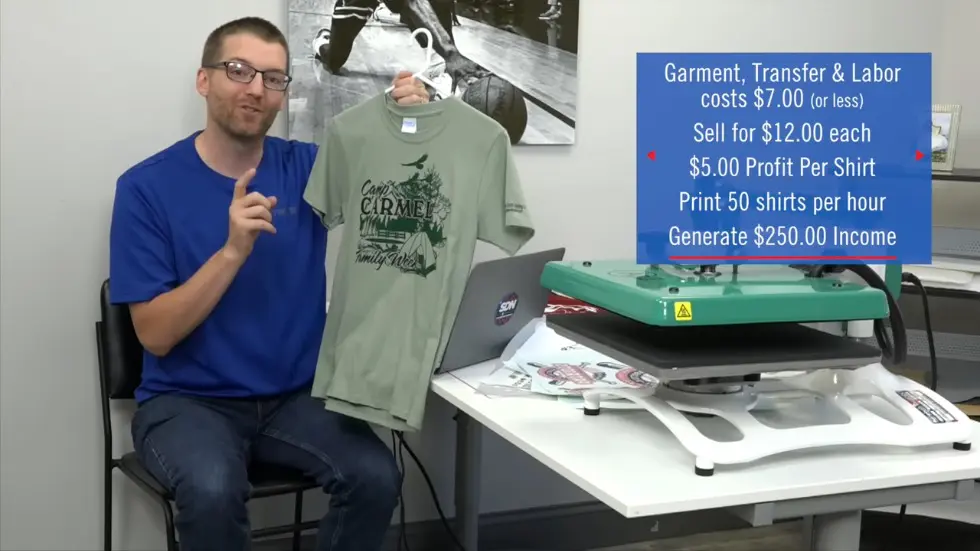

- Heat press is a high-profit machine that can generate income from home.

- Screen printed transfers from Transfer Express are a great way to start a t-shirt business.

- Printing a shirt with a garment, labor, and transfer can cost $7 or less.

- Printing 50 shirts in less than an hour can generate $250 in income.

- Ordering the right transfer, having an accurate press, and finding customers are key to success.

- Screen printed transfers, heat transfer vinyl, print cut heat transfer vinyl, and digital screen printed transfers are the four print methods for heat transfer.

- Accuracy in time, temperature, and pressure is crucial for high-quality and long-lasting items.

- The A to Z heat press is specifically designed for startup home decorators who want to get into heat printing with quality.

- Programmable press with accurate digital time and temperature control, semi-threadable design, adjustable pressure, and 15 by 15 inch printing surface are the features of the A to Z heat press.

How to Start a T-Shirt Business at Home | Key Things to Know! - YouTube

Introduction

- Heat press is a high-profit machine that can generate income from home.

- Screen printed transfers from Transfer Express are a great way to start a t-shirt business.

- Printing a shirt with a garment, labor, and transfer can cost $7 or less.

- Printing 50 shirts in less than an hour can generate $250 in income.

- Ordering the right transfer, having an accurate press, and finding customers are key to success.

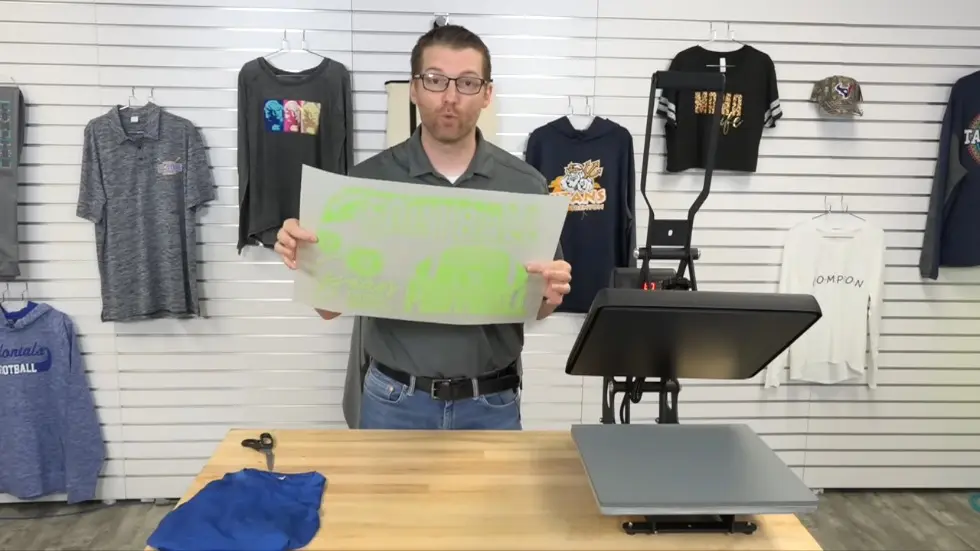

Screen Printed Transfers

- Screen printing is a popular technology for decorating apparel at retail.

- Screen printed transfers use actual plastisol ink on a paper carrier.

- Multiple images can be grouped onto one sheet as long as they use the same colors.

- Transfers can be ordered and received in groups of 15 or more.

- Trimming and heat applying the transfer creates a finished result that feels great.

Heat Transfer Vinyl

- Heat transfer vinyl, or cadcut, is popular for low quantities and personalization.

- Designs are cut in the mirror image and weeded before pressing.

- Multiple colors require layering and piecing together on the shirt.

- Special effects like reflective, glitter, metallics, and foils are possible.

- Not ideal for fine detail artwork or high color counts.

How to Start a T-Shirt Business at Home | Key Things to Know! - YouTube

Print Cut Heat Transfer Vinyl

- Print cut heat transfer vinyl requires a printer cutter to print all colors onto clear or white vinyl.

- As many colors as desired can be printed onto a transfer without increasing cost.

- Weeding, masking, and heat applying the transfer creates a finished result.

- Great for t-shirts and athletic wear, with special effect finishes like glitter.

- Best for designs with three or more colors and low quantities.

Digital Screen Printed Transfers

- New technology for 2020 that combines digital printing and screen printing.

- Great for jobs that are too small for screen printing or too detailed for print cut vinyl.

- Allows for full-color designs without the need for layering or weeding.

- Heat applying the transfer creates a finished result that feels great.

- Available from Transfer Express.

Core 4 Print Technologies

- Four print methods for heat transfer: screen printed transfers, digital transfers, vinyl cutters, and print/cut systems.

- Screen printed transfers are best for larger quantities and simple designs.

- Digital transfers are best for smaller quantities and complex designs.

- Vinyl cutters are best for one or two color designs and small quantities.

- Print/cut systems are best for full-color designs and small to medium quantities.

What to Use When Grid

- A grid used by large contract decorators to quickly select the right transfer product.

- Includes the four print techniques discussed earlier and a number of colors in the design and quantity of garments.

- Helps to figure out the lowest cost option that allows you to print your job and adds consistency into your selection.

- High-quality and durable products.

- Water-based transfer is a new technology that is most like screen printed transfers but with water-based ink.

Water-Based Screen Printed Transfer

- A premium finish that is buttery soft on the garment and has stretch.

- Can apply to practically any fabric, including nylon jackets.

- Called Aqua True.

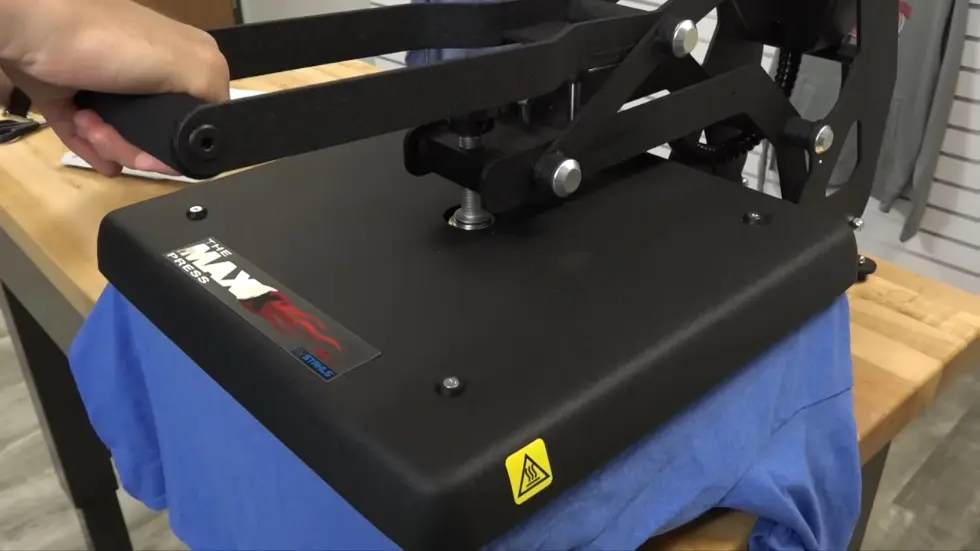

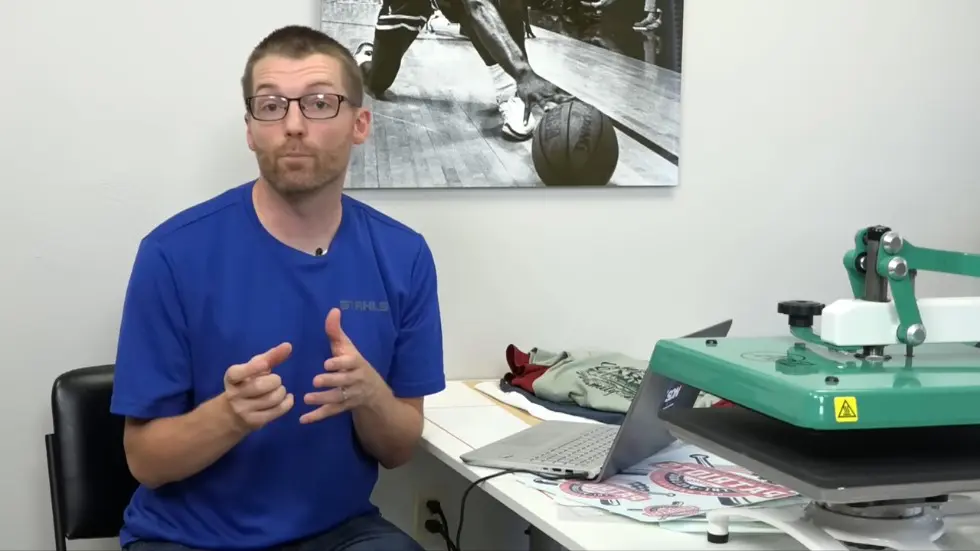

Investing in the Right Heat Press

- Accuracy in time, temperature, and pressure is crucial for high-quality and long-lasting items.

- Stahls manufactures a wide selection of heat presses, from entry-level to super high-end.

- The A to Z heat press is specifically designed for startup home decorators who want to get into heat printing with quality.

- Features include a swing-away design for a complete heat-free workspace, a flat pressing area, and accuracy in time, temperature, and pressure.

Screen Printing Transfers

- Preheat garment by locking it down for a few seconds.

- Position screen printed transfer onto garment.

- Bring heat press back into location and lock it down.

- Heat apply transfer for 4-6 seconds.

- Peel back of design to reveal completed result.

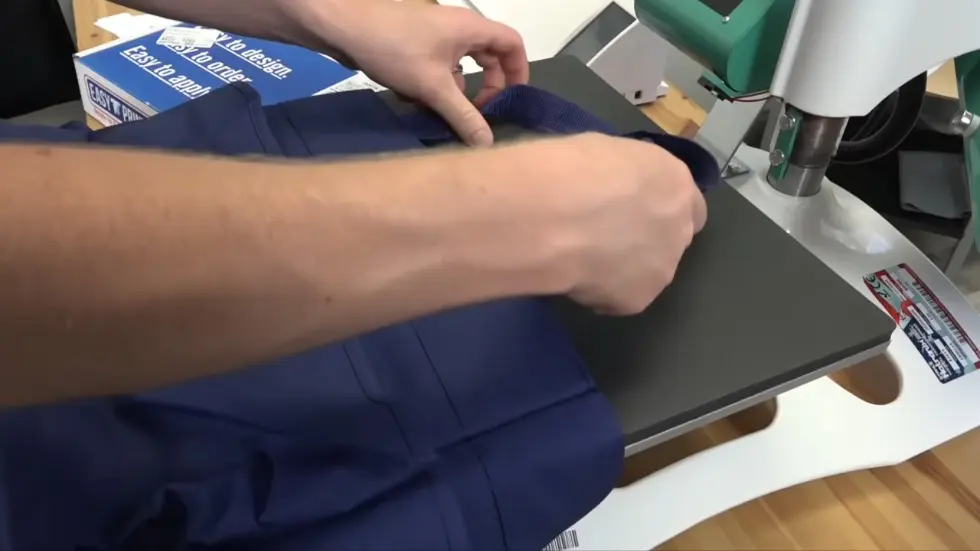

Heat Transfer Vinyl

- Reduce temperature on digital control board to 300 degrees.

- Apply glitter design that has been cut on a vinyl cutter.

- Split item open and slide a heat printing pillow underneath.

- Adjust pressure until accurate pressure is achieved on the print location.

- Heat apply vinyl for 10 seconds.

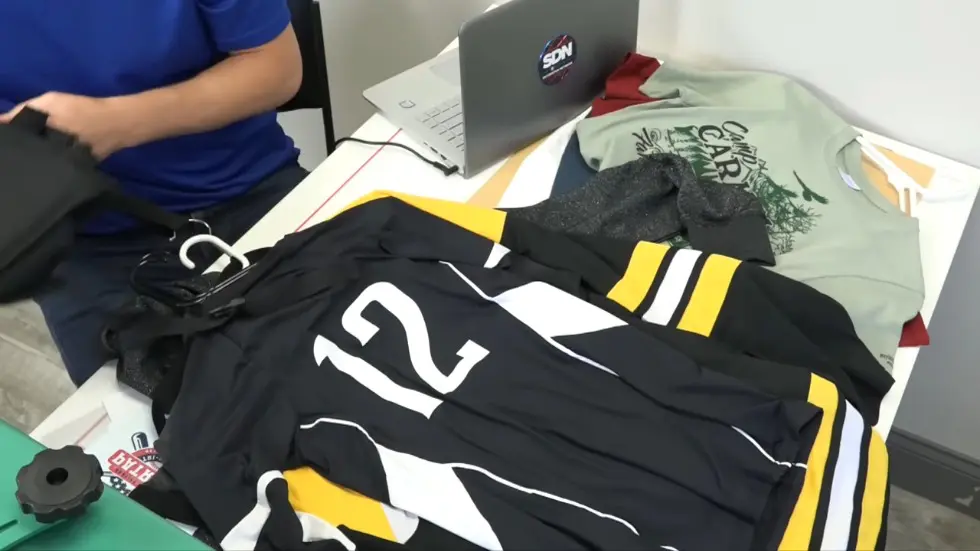

Team Uniforms

- Use a heat printing pillow to separate layers of mesh on a football jersey.

- Position pre-cut numbers onto jersey.

- Heat apply thermofilm for 8 seconds.

- Flip jersey to print the back and readjust pillow.

- Heat apply thermofilm for 8 seconds on the back.

A to Z Heat Press Features

- Programmable press with accurate digital time and temperature control.

- Can print screen printed transfers and heat transfer vinyl.

- Has a semi-threadable design to print on items with seam structure.

- Adjustable pressure for accurate pressure on print location.

- 15 by 15 inch printing surface for plenty of room to decorate.

Thermofilm for Athletic Uniforms

- Preheat the back of the uniform

- Position the back number into place

- Use thermofilm for the fastest and easiest way to number athletic uniforms

- Heat press makes applying thermal fill numbers easier than ever

- Decorate a jacket using semi-threadable and digital full-color transfer

Features of A to Z Heat Press

- Digital time and temperature for accurate quality results

- Pressure adjustment to accommodate the thickness of the item

- Semi-threadable base for printing more items

- Swing away design for a completely heat-free workspace

- Convenient handle for returning the machine back to the pressing location

- Interchangeable attachments for loading another size if needed

ROI and Profit Potential

- A to Z Heat Press is a great startup option for less than $700

- Selling 50 shirts for $12 each with a $5 profit potential means $250 an hour

- Sell three jobs of 50 shirts or six jobs of 25 shirts to pay off the machine

- Screen printed transfers can print 150 shirts in less than three hours

- Heat press can print more than just t-shirts

Types of Customers and Products

- Sports and spirit market for event shirts and customized items

- Seat covers can be customized with heat transfer vinyl

- Items that can be decorated on the heat press as long as they can be flattened

- Heat press can achieve different finishes for different designs

- Heat press can reach a variety of customers and markets

Types of Heat Transfer Methods

- Stretchy materials that work on stretch fabrics

- Highly durable twill materials that can just be heat applied that look like they're sewn on

- Sublimated patches that can be applied with the heat press to get a full color twill design

- Electric heat transfer vinyl for down the leg print

- Foil for a baseball mom shirt

- Mixing and matching different materials to have your results stand out

Markets to Sell to with Your Heat Press

- Sports teams and schools for fan apparel and support

- Promotional products to promote a brand as well as small business apparel

- Printing graphic tees or even a clothing line

- Personalization for back-to-school opportunities, holidays, and more

- Group orders for events like walks and runs, tie dye shirts for county fairs, and reflective racing gear

- Municipalities for police, fire, EMS, and paramedic apparel

Customization Examples

- Glitter and pattern foil combination for a unique look

- High-end blank items like glitter hoodies paired with glitter and flat heat transfer vinyl

- Electric and flat material used to customize a flannel shirt with all sorts of placement and detailing in the graphic

- Personalized stockings, handbags, and birthday shirts

- Full color digital screen printed transfer and flock personalization for events like spring break and walks/runs

- Reflective finishes for industries like safety or construction

Opportunities for Revenue

- Expanding the items that you're offering

- Printing to order as you realize your sale through your ecommerce store or Etsy

- Printing on onesies, which are CPSIA compliant for children's apparel

- Customization with higher end styles for female fashion in particular

- Easy printing for group orders with events

- Many opportunities await in your own local community

Product Selection and Resources

- Heat press printing from home can be simple and achieve various looks in different markets.

- Order completed items from Transfer Express and Stahls.

- Marketing kit included with heat press purchase from Stahls or Transfer Express.

- Heat transfer vinyl samples included with A to Z heat press investment.

- Stahls TV YouTube channel has thousands of hours of footage teaching how to print items.

Marketing and Sales

- Figure out what market to approach and who the customer will be.

- Write down the top five customer types to sell to.

- Brainstorm a list of sales for the small businesses you will call first.

- Read "Marketing Made Simple" by Donald Miller for help with marketing plan and finding your voice.

- Comment on the video with any questions and Stahls' goal is to help you be successful in your apparel decorating business.

Watch the video on YouTube:

How to Start a T-Shirt Business at Home | Key Things to Know! - YouTube

Read also:

- Full Print On-Demand Tutorial For Beginners (2023 Version) (smartworldoptions.com)

- How To Start Print on Demand With $0 | STEP BY STEP | NO SHOPIFY & NO ADS! (FREE COURSE) (smartworldoptions.com)

- BEST Way to List on Etsy with Printify | Everything You NEED to KNOW (smartworldoptions.com)

Related summaries of videos: